Complex fractures present unique challenges in orthopedic surgery, demanding specialized fixation methods that provide both stability and precision. Cannulated screws have emerged as a cornerstone technology in addressing these intricate bone injuries, offering surgeons enhanced control and superior patient outcomes. These hollow-core fasteners revolutionize fracture repair by combining the mechanical strength needed for bone stabilization with the guidance capabilities essential for accurate placement. Understanding the sophisticated design principles behind cannulated screws reveals why they have become indispensable tools in modern trauma surgery and orthopedic reconstruction.

Fundamental Design Architecture of Cannulated Screws

Hollow Core Engineering Principles

The defining characteristic of cannulated screws lies in their hollow central channel, which serves multiple critical functions throughout the surgical procedure. This cylindrical void extends the entire length of the screw, typically measuring between 1.5mm to 3.5mm in diameter depending on the screw size and intended application. The hollow core allows for guide wire insertion, enabling surgeons to establish precise trajectory paths before committing to final screw placement. This design feature significantly reduces the risk of malposition and provides real-time feedback during insertion through fluoroscopic imaging.

Manufacturing these hollow channels requires advanced machining techniques that maintain structural integrity while creating the necessary internal pathway. The wall thickness surrounding the cannulation must be carefully calculated to preserve the screw's mechanical properties, particularly its resistance to bending and torsional forces. Engineers employ finite element analysis to optimize the balance between cannulation size and remaining material strength, ensuring that the hollow design does not compromise the screw's ability to withstand physiological loads.

Thread Geometry and Pitch Optimization

Thread design in cannulated screws involves sophisticated geometric considerations that directly impact their holding power and insertion characteristics. The thread pitch, depth, and angle are meticulously engineered to maximize purchase in both cortical and cancellous bone while minimizing insertion torque. Variable thread pitches along the screw length create differential compression zones, allowing surgeons to achieve optimal fracture reduction and maintain compression throughout the healing process.

Advanced thread profiles incorporate features such as cutting flutes and self-tapping capabilities, reducing the need for extensive pre-drilling and streamlining surgical procedures. The thread design also considers the weakening effect of the central cannulation, compensating through increased thread engagement length and optimized stress distribution patterns. Modern cannulated screws often feature partially threaded configurations, where the smooth shaft portion facilitates lag screw mechanics while the threaded portion provides secure anchoring in the target bone segment.

Material Science and Biocompatibility Considerations

Titanium Alloy Composition and Properties

Cannulated screws are predominantly manufactured from titanium alloys, specifically Ti-6Al-4V, which offers an exceptional combination of strength, biocompatibility, and corrosion resistance. This material choice is crucial for implants that may remain in the body permanently, as it demonstrates excellent osseointegration properties and minimal inflammatory response. The titanium alloy's modulus of elasticity more closely matches that of bone compared to stainless steel alternatives, reducing stress shielding effects that can lead to bone resorption around the implant.

Surface treatments and coatings further enhance the biocompatibility and performance characteristics of cannulated screws. Anodization processes create controlled oxide layers that improve corrosion resistance and provide color coding for easy identification during surgery. Some manufacturers incorporate hydroxyapatite coatings or surface texturing to promote bone ingrowth and improve long-term fixation stability. These surface modifications are particularly important in the cannulated design, where the internal surfaces must also maintain biocompatibility standards.

Mechanical Property Requirements

The mechanical properties of cannulated screws must meet stringent requirements to ensure reliable performance under physiological loading conditions. Tensile strength typically exceeds 900 MPa, while yield strength surpasses 800 MPa, providing adequate safety margins for clinical applications. The hollow design necessitates careful attention to fatigue resistance, as stress concentrations around the cannulation can potentially initiate crack propagation under cyclic loading conditions.

Quality control protocols for cannulated screws include comprehensive mechanical testing regimens that evaluate both static and dynamic performance characteristics. Pull-out strength testing verifies the screw's ability to resist extraction forces, while torsional testing confirms adequate resistance to rotational loads during insertion and service. Fatigue testing simulates years of physiological loading to ensure long-term reliability, with particular emphasis on the stress concentration effects introduced by the central cannulation.

Surgical Applications and Clinical Advantages

Fracture-Specific Design Considerations

Different types of complex fractures require specialized cannulated screw designs tailored to their unique biomechanical demands. Femoral neck fractures, for instance, benefit from cannulated screws with specific length and diameter combinations that provide optimal purchase in both the femoral head and neck regions. Hip fracture fixation often employs multiple parallel cannulated screws arranged in triangular or inverted triangle configurations to create a mechanically stable construct that resists both compression and rotational forces.

Scaphoid fractures represent another critical application where cannulated screws excel due to their ability to navigate the complex anatomy of the wrist. The central cannulation allows for precise positioning along the scaphoid's central axis, maximizing compression across the fracture site while avoiding damage to surrounding soft tissues. The headless design of many scaphoid cannulated screws prevents impingement with adjacent carpal bones and allows for subchondral placement that maintains joint function.

Minimally Invasive Surgical Techniques

The guide wire compatibility of cannulated screws enables minimally invasive surgical approaches that reduce soft tissue damage and accelerate patient recovery. Percutaneous insertion techniques utilize small skin incisions and specialized instrumentation to place screws with minimal disruption to surrounding muscles and fascia. This approach is particularly valuable in elderly patients or those with multiple comorbidities where extensive surgical exposure carries increased risks.

Image-guided insertion protocols leverage the radiopaque properties of guide wires to provide real-time visualization during screw placement. Fluoroscopic guidance allows surgeons to verify correct positioning and trajectory before irreversibly committing to screw insertion. Advanced navigation systems can integrate preoperative CT scan data with intraoperative imaging to create three-dimensional guidance systems that further enhance accuracy and safety during cannulated screw insertion procedures.

Design Optimization for Specific Anatomical Regions

Hip and Femoral Applications

Cannulated screws designed for hip fractures incorporate specific features that address the unique biomechanical environment of the proximal femur. Larger diameter screws, typically 6.5mm to 7.3mm, provide increased resistance to the high compressive and shear forces encountered in this weight-bearing region. The thread design often features aggressive cutting characteristics to facilitate insertion through dense cortical bone while maintaining strong purchase in the softer cancellous bone of the femoral head.

Variable pitch threading in hip cannulated screws creates lag screw mechanics that compress fracture fragments together during insertion. This compression effect is crucial for promoting bone healing and preventing fracture displacement under physiological loads. Some designs incorporate washers or flanged heads that distribute loads over larger surface areas, reducing the risk of screw cut-out through osteoporotic bone that is commonly encountered in elderly hip fracture patients.

Hand and Wrist Specialization

Smaller diameter cannulated screws designed for hand and wrist applications must balance miniaturization with adequate mechanical strength. Diameters ranging from 2.0mm to 4.0mm accommodate the delicate anatomy while providing sufficient fixation strength for these lower-load environments. Headless designs are particularly important in these locations to prevent impingement with tendons, ligaments, and adjacent bones that could limit joint motion or cause pain.

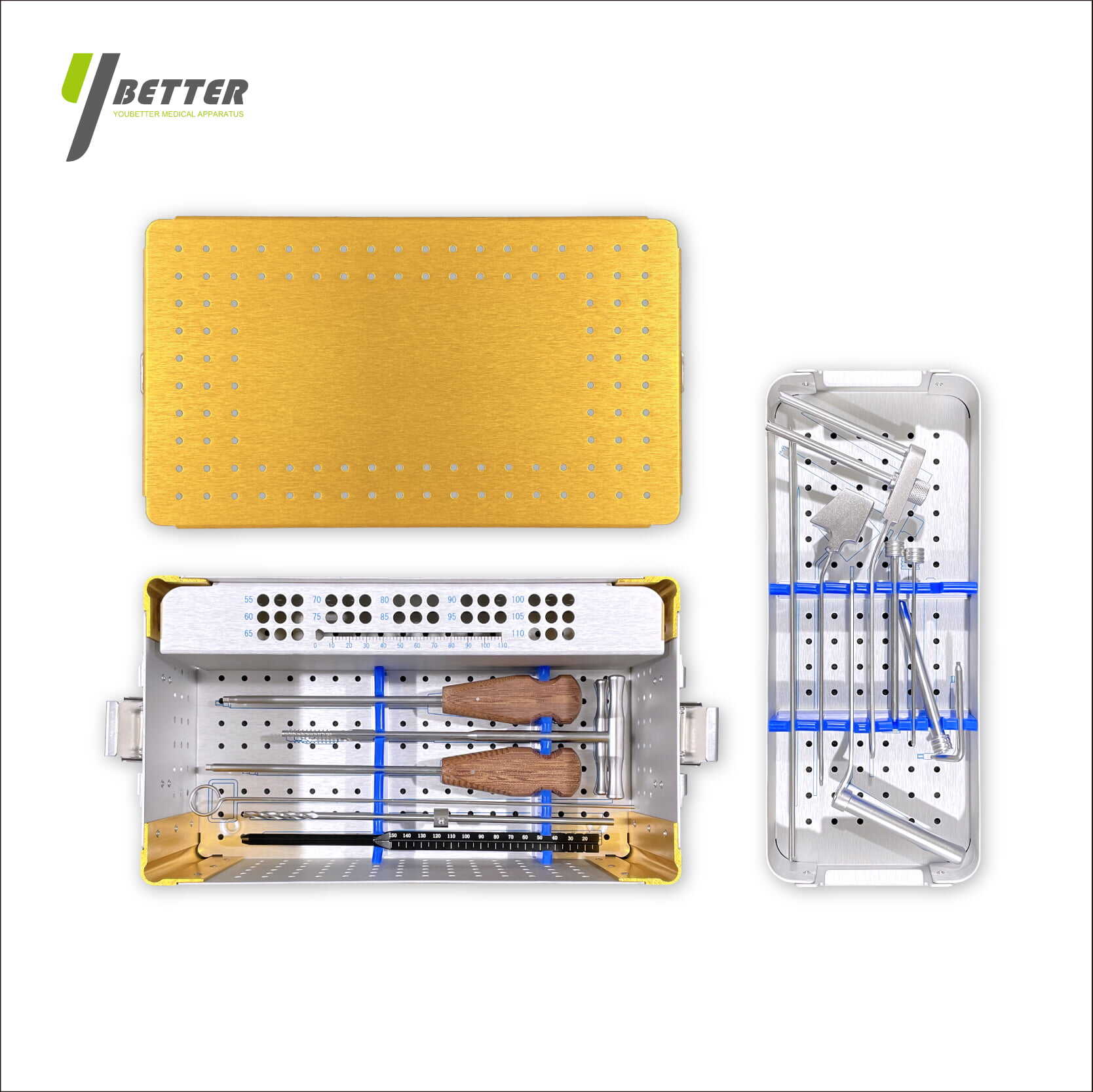

The shorter length requirements for hand and wrist applications allow for different thread configurations that maximize holding power within limited bone stock. Full threading is often employed to provide maximum bone engagement, while specialized tip designs facilitate insertion through small, curved bones like the scaphoid. Color-coded instrumentation systems help surgeons quickly identify appropriate sizes during surgery, where time efficiency is crucial for maintaining fracture reduction and minimizing anesthesia exposure.

Manufacturing Processes and Quality Assurance

Precision Machining Techniques

Manufacturing cannulated screws requires sophisticated machining processes that can create precise internal and external geometries while maintaining tight dimensional tolerances. Computer numerical control (CNC) machining centers equipped with specialized tooling systems produce the complex thread profiles and hollow cores simultaneously. The cannulation process typically involves gun drilling or similar deep-hole drilling techniques that can create straight, smooth-walled channels through the entire screw length.

Quality control measures during manufacturing include dimensional verification using coordinate measuring machines and optical inspection systems that can detect microscopic defects. Surface finish requirements are particularly stringent for the internal cannulation, as rough surfaces could interfere with guide wire passage or create stress concentration points. Advanced inspection techniques such as eddy current testing can detect subsurface defects that might not be visible through conventional optical methods.

Sterilization and Packaging Considerations

The hollow design of cannulated screws presents unique challenges for sterilization processes, as the internal surfaces must be thoroughly cleaned and sterilized without compromising the screw's mechanical properties. Gamma radiation sterilization is commonly employed due to its ability to penetrate the internal channels effectively while maintaining material integrity. Ethylene oxide sterilization may be used for certain applications, though longer aeration times are required to ensure complete removal of residual gas from the cannulated spaces.

Packaging systems for cannulated screws must protect both the external surfaces and internal channels from contamination during storage and handling. Individual packaging with protective caps or plugs prevents debris accumulation within the cannulation while maintaining sterility. Traceability systems track each screw through manufacturing, sterilization, and distribution processes to ensure quality control and enable rapid response to any potential issues that might arise in clinical use.

Future Developments and Innovations

Smart Implant Technologies

Emerging technologies in cannulated screw design include the integration of sensors and monitoring capabilities that can provide real-time information about healing progress and implant performance. Miniaturized strain gauges embedded within the screw structure could monitor load transfer patterns and detect early signs of fixation failure or bone healing complications. Wireless communication systems would allow for remote monitoring without requiring invasive procedures to assess implant status.

Biodegradable cannulated screws represent another frontier in implant technology, utilizing materials that gradually dissolve as bone healing progresses. These designs eliminate the need for implant removal procedures while providing temporary fixation during the critical healing period. Advanced polymer compositions and ceramic materials are being investigated for their potential to match the mechanical requirements of cannulated screws while offering controlled degradation profiles.

Additive Manufacturing Applications

Three-dimensional printing technologies are revolutionizing cannulated screw manufacturing by enabling patient-specific customization and complex internal geometries that would be impossible to achieve through conventional machining. Selective laser melting and electron beam melting processes can create titanium cannulated screws with internal lattice structures that promote bone ingrowth while maintaining necessary mechanical strength. These additive manufacturing techniques also enable rapid prototyping of new designs and small-batch production for specialized applications.

Surface modification through additive manufacturing includes the creation of controlled porosity and texture patterns that enhance osseointegration. Graded material properties can be achieved within a single screw, with different mechanical characteristics in various regions to optimize performance for specific anatomical requirements. These manufacturing advances promise to further improve the clinical outcomes and expand the applications of cannulated screws in complex fracture management.

FAQ

What makes cannulated screws more effective than solid screws for complex fractures?

Cannulated screws offer superior accuracy through guide wire placement, allowing surgeons to establish optimal trajectory and positioning before final insertion. The hollow design enables real-time fluoroscopic visualization and reduces the risk of malposition, while maintaining equivalent mechanical strength to solid screws. This precision is particularly crucial in complex fractures where anatomical landmarks may be distorted and exact placement is essential for successful healing.

How do surgeons determine the appropriate size and length for cannulated screws?

Screw selection depends on multiple factors including bone density, fracture pattern, anatomical location, and patient-specific considerations. Preoperative imaging provides initial measurements, while intraoperative assessment using guide wires confirms appropriate length and diameter. Specialized measuring instruments and depth gauges ensure accurate sizing, with safety margins incorporated to account for individual anatomical variations and surgical technique requirements.

What are the potential complications associated with cannulated screw fixation?

Common complications include screw loosening, cut-out through osteoporotic bone, and hardware-related irritation. The cannulated design may occasionally experience guide wire breakage or retention if proper technique is not followed. Infection risks are similar to other implants, while mechanical failures such as screw fracture are rare but possible under extreme loading conditions. Proper surgical technique and patient selection minimize these risks significantly.

Can cannulated screws be removed after fracture healing, and when is removal necessary?

Cannulated screws can be removed through standard surgical techniques when clinically indicated, though removal is not routinely necessary unless complications arise. Indications for removal include hardware irritation, infection, or patient preference in younger individuals. The removal process typically involves accessing the screw head and using standard extraction instruments, with the hollow design generally not complicating the removal procedure compared to solid screws.

Table of Contents

- Fundamental Design Architecture of Cannulated Screws

- Material Science and Biocompatibility Considerations

- Surgical Applications and Clinical Advantages

- Design Optimization for Specific Anatomical Regions

- Manufacturing Processes and Quality Assurance

- Future Developments and Innovations

-

FAQ

- What makes cannulated screws more effective than solid screws for complex fractures?

- How do surgeons determine the appropriate size and length for cannulated screws?

- What are the potential complications associated with cannulated screw fixation?

- Can cannulated screws be removed after fracture healing, and when is removal necessary?