The evolution of medical device manufacturing has transformed the way surgeons approach complex facial reconstructions and orthopedic procedures. Modern maxillofacial plate manufacturing represents a pinnacle of precision engineering where advanced technology meets surgical excellence. Today's manufacturing processes incorporate cutting-edge innovations that ensure every component meets the exacting standards required for successful patient outcomes. These technological advances have revolutionized how medical professionals approach facial trauma repair, jaw reconstruction, and various other surgical applications that demand exceptional accuracy and reliability.

Advanced Manufacturing Technologies in Medical Device Production

Computer-Aided Design and Manufacturing Systems

Computer-aided design and manufacturing systems have fundamentally transformed the precision capabilities within maxillofacial plate manufacturing. These sophisticated software platforms enable engineers to create detailed three-dimensional models that account for the complex anatomical variations found in human facial structures. The integration of CAD systems allows manufacturers to simulate stress distributions, evaluate material properties, and optimize plate geometry before any physical production begins. This digital-first approach significantly reduces the likelihood of design flaws and ensures that each component meets the stringent requirements necessary for surgical applications.

Manufacturing teams utilize advanced CAM software to translate digital designs into precise machining instructions that control automated production equipment. These systems can maintain tolerances within micrometers, ensuring that every surface finish, hole diameter, and contour matches the exact specifications required for proper surgical fit and function. The seamless integration between design and manufacturing processes eliminates many of the human errors that traditionally plagued medical device production, resulting in consistently superior product quality.

Precision Machining and Surface Treatment Technologies

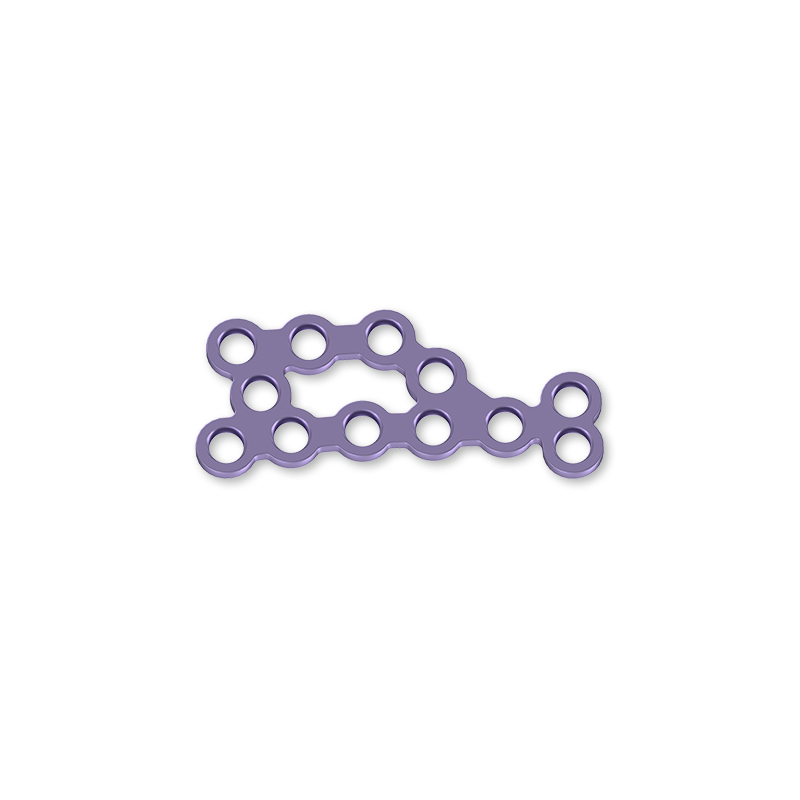

Modern machining centers equipped with multi-axis capabilities deliver unprecedented accuracy in creating complex geometries required for maxillofacial applications. These machines can simultaneously control multiple cutting tools while maintaining positional accuracy that exceeds traditional manufacturing methods by several orders of magnitude. The ability to machine intricate features such as anatomically contoured surfaces, precise screw holes, and smooth transitional zones requires sophisticated tooling strategies and real-time monitoring systems that ensure dimensional stability throughout the production process.

Surface treatment technologies have evolved to provide enhanced biocompatibility and improved integration with human tissue. Advanced anodizing processes, plasma treatments, and specialized coatings create surfaces that promote osseointegration while minimizing the risk of adverse reactions. These treatments are applied using precisely controlled parameters that ensure uniform coverage and optimal surface characteristics across the entire implant surface, contributing to better long-term patient outcomes.

Quality Assurance and Measurement Systems

Coordinate Measuring Machine Applications

Coordinate measuring machines represent the gold standard for dimensional verification in maxillofacial plate manufacturing facilities. These precision instruments can measure complex three-dimensional geometries with sub-micron accuracy, providing manufacturers with the confidence that every produced component meets the exact specifications required for surgical success. CMM systems utilize sophisticated probe technologies and advanced software algorithms to capture thousands of measurement points across critical surfaces, generating comprehensive reports that document compliance with dimensional tolerances.

The integration of CMM systems into production workflows enables real-time quality monitoring that can detect dimensional variations before they impact product quality. Statistical process control methodologies built into modern CMM software help manufacturing teams identify trends and implement corrective actions that maintain consistent output quality. This proactive approach to quality management significantly reduces waste, improves efficiency, and ensures that surgeons receive products that perform predictably in clinical applications.

Non-Destructive Testing Methods

Non-destructive testing methods provide essential quality assurance capabilities that verify the internal integrity of manufactured components without compromising their usability. Advanced ultrasonic testing systems can detect subsurface defects, porosity, and material inconsistencies that might not be visible through visual inspection alone. These testing protocols are particularly critical in maxillofacial plate manufacturing where internal flaws could lead to catastrophic failure during surgical procedures or long-term implant service.

X-ray inspection systems and computed tomography scanning provide detailed internal imaging that reveals the complete three-dimensional structure of manufactured components. These technologies enable quality assurance teams to verify material density distribution, detect internal voids, and confirm that welded or bonded joints meet the required strength specifications. The implementation of comprehensive NDT protocols ensures that only components meeting the highest quality standards reach surgical environments.

Material Science Innovations

Biocompatible Alloy Development

The development of advanced biocompatible alloys has significantly enhanced the performance characteristics available in modern maxillofacial plate manufacturing. Titanium-based alloys continue to evolve with improved mechanical properties that better match the elastic modulus of human bone tissue, reducing stress shielding effects and promoting better long-term integration. These materials undergo extensive testing to ensure they meet the stringent biocompatibility requirements established by regulatory agencies while providing the mechanical strength necessary for demanding surgical applications.

Research into new alloy compositions focuses on optimizing corrosion resistance, fatigue performance, and manufacturing processability. Advanced metallurgical techniques such as powder metallurgy and additive manufacturing enable the creation of complex microstructures that enhance material properties beyond what is achievable through traditional processing methods. These innovations directly translate into improved patient outcomes through better implant longevity and reduced complications.

Additive Manufacturing Applications

Additive manufacturing technologies have opened new possibilities for creating patient-specific solutions that were previously impossible to achieve through conventional manufacturing methods. Three-dimensional printing capabilities enable the production of complex internal geometries, variable density structures, and custom anatomical contours that perfectly match individual patient anatomy. These technologies are particularly valuable in maxillofacial plate manufacturing where anatomical variations between patients can be significant.

The ability to manufacture components with integrated features such as internal channels for drug delivery, porous structures for tissue ingrowth, and graduated stiffness zones represents a fundamental advancement in implant design capabilities. Additive manufacturing processes continue to improve in terms of resolution, material options, and production speed, making these technologies increasingly viable for both custom and standard product manufacturing.

Digital Integration and Process Automation

Enterprise Resource Planning Systems

Enterprise resource planning systems provide the digital backbone that coordinates all aspects of modern maxillofacial plate manufacturing operations. These comprehensive software platforms integrate design data, production schedules, quality records, and regulatory compliance documentation into unified systems that enable real-time visibility across the entire manufacturing process. ERP systems help manufacturers maintain the detailed traceability records required by medical device regulations while optimizing resource utilization and production efficiency.

The integration of ERP systems with manufacturing execution systems creates seamless data flow that eliminates manual data entry errors and ensures that all production activities are properly documented. This digital integration enables manufacturers to implement sophisticated scheduling algorithms that optimize equipment utilization while maintaining the flexibility to accommodate urgent orders and custom product requirements. The result is improved delivery performance and enhanced customer satisfaction.

Automated Inspection and Sorting Systems

Automated inspection and sorting systems represent the cutting edge of quality assurance technology in medical device manufacturing. These systems utilize advanced machine vision technologies, artificial intelligence algorithms, and robotic handling systems to perform comprehensive quality evaluations at production speeds that far exceed human capabilities. Automated systems can detect surface defects, dimensional variations, and material inconsistencies with remarkable accuracy and repeatability.

The implementation of automated inspection systems reduces the variability associated with human inspection while providing complete documentation of quality decisions. Machine learning algorithms continuously improve inspection accuracy by learning from historical data and feedback from downstream processes. This evolutionary capability ensures that quality standards continuously improve over time, contributing to better patient outcomes and reduced warranty costs.

Regulatory Compliance and Documentation

ISO Standards Implementation

Implementation of ISO standards provides the framework for establishing robust quality management systems that ensure consistent product quality in maxillofacial plate manufacturing. ISO 13485 specifically addresses the unique requirements of medical device manufacturing, establishing comprehensive requirements for design controls, risk management, and post-market surveillance. These standards require manufacturers to implement systematic approaches to process validation, change control, and corrective action management that directly contribute to improved product reliability.

The adoption of ISO standards creates a culture of continuous improvement where manufacturing processes are regularly evaluated and optimized based on performance data and customer feedback. This systematic approach to quality management helps manufacturers identify potential issues before they impact product quality and implement preventive measures that enhance overall system reliability. Compliance with international standards also facilitates market access and builds customer confidence in product quality.

Traceability and Documentation Systems

Comprehensive traceability and documentation systems provide the detailed records necessary to support regulatory compliance and post-market surveillance activities. These systems track every aspect of component production from raw material receipt through final packaging and shipment, creating a complete audit trail that can be accessed years after product delivery. Traceability systems are particularly critical in medical device manufacturing where the ability to quickly identify and contact affected patients in the event of a product issue can be life-saving.

Digital documentation systems ensure that all quality records, test results, and manufacturing parameters are accurately captured and securely stored. Electronic records eliminate the risks associated with paper-based systems while providing improved searchability and data analysis capabilities. These systems support regulatory submissions, customer audits, and internal quality reviews by providing immediate access to comprehensive manufacturing data.

FAQ

What are the key technologies driving accuracy improvements in maxillofacial plate manufacturing

The primary technologies enhancing accuracy include computer-aided design and manufacturing systems, precision multi-axis machining centers, coordinate measuring machines, and advanced surface treatment processes. These technologies work together to achieve dimensional tolerances within micrometers while ensuring optimal surface characteristics for biocompatibility. Additionally, non-destructive testing methods such as ultrasonic inspection and computed tomography provide comprehensive quality verification without compromising product integrity.

How do additive manufacturing techniques contribute to improved surgical outcomes

Additive manufacturing enables the creation of patient-specific implants that perfectly match individual anatomical requirements, leading to better surgical fit and improved integration with surrounding tissues. These technologies also allow for the incorporation of complex internal geometries such as porous structures for tissue ingrowth and internal channels for targeted drug delivery. The ability to create custom solutions addresses the significant anatomical variations between patients that cannot be accommodated through standard manufacturing approaches.

What role does automated inspection play in ensuring product quality

Automated inspection systems provide consistent, repeatable quality evaluation that exceeds human capabilities in terms of speed and accuracy. These systems utilize machine vision technologies and artificial intelligence algorithms to detect surface defects, dimensional variations, and material inconsistencies with remarkable precision. The continuous operation capability of automated systems enables 100% inspection of production output while generating comprehensive documentation that supports regulatory compliance and quality improvement initiatives.

How do quality management systems support regulatory compliance in medical device manufacturing

Quality management systems based on ISO 13485 standards provide the structured framework necessary for maintaining regulatory compliance throughout the product lifecycle. These systems establish comprehensive requirements for design controls, risk management, process validation, and post-market surveillance that directly support FDA and international regulatory requirements. The systematic approach to documentation and change control ensures that all manufacturing activities are properly controlled and traceable, facilitating regulatory submissions and supporting post-market safety monitoring activities.

Table of Contents

- Advanced Manufacturing Technologies in Medical Device Production

- Quality Assurance and Measurement Systems

- Material Science Innovations

- Digital Integration and Process Automation

- Regulatory Compliance and Documentation

-

FAQ

- What are the key technologies driving accuracy improvements in maxillofacial plate manufacturing

- How do additive manufacturing techniques contribute to improved surgical outcomes

- What role does automated inspection play in ensuring product quality

- How do quality management systems support regulatory compliance in medical device manufacturing